Characteristics of Metal bellows

Have you ever wondered just what metal bellows are or what they're used for? Metal bellows are an innovative and component that versatile have many advantages and can be used in a wide range of applications. , we will explore the traits of metal bellows, including their advantages, innovation, safety, usage, how to use, service, quality, and application.

Attributes of Metal Bellows

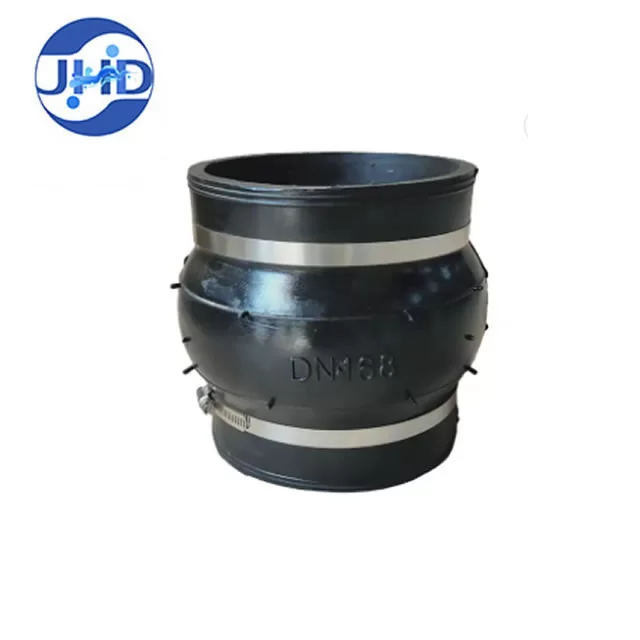

Metal bellows have numerous advantages over other types of expansion joints. These are generally produced of metal, meaning that they are excessively durable and can withstand pressures being high conditions. Also, metal bellows are resistant to corrosion and can endure for several years without requiring to be changed.

Another benefit of metal bellows is the freedom. The Metal bellows can be easily compressed or expanded to accommodate changes in temperature, pressure, or movement since they will be made of thin, flexible material. This means they've been ideal for use in a range that wide of, such as for example for instance in engines and pipelines

.

.

Innovation in Metal Bellows

In current years, there were innovations which can be many the design and manufacture of metal bellows. These innovations have resulted in bellows that tend to be more durable, more flexible, and easier to use than ever before before.

One of the most important innovations in metal hoses bellows is the usage of new materials and strategies that are manufacturing. For instance, some bellows are now actually made from titanium or any other metals which can be exotic that are incredibly strong and resistant to corrosion. Furthermore, some bellows are now made laser-welding that using other advanced manufacturing practices, which benefits in joints that are far more precise and have actually fewer defects.

Safety features of Metal Bellows

When metal that using, it is important to make sure that they are set up precisely and used safely. Some safety that important of metal bellows include:

- Pressure ratings: All bellows are rated for a pressure that specific, and it is important to ensure that they truly are perhaps not used outside with this range.

- Temperature range: likewise, all bellows are rated for a temperature that specific, and it is important to make sure they've been maybe not exposed to temperatures away from this range.

- Corrosion resistance: according to the application, it may be important to make sure the bellows are made of a material that resistant to corrosion.

How to Use Metal Bellows

Using metal bellows is not difficult and simple. Allow me to share some steps which are fundamental

1. determine the size that's right type of bellows for your application.

2. Install the bellows according to the manufacturer's directions, making certain it is properly guaranteed and aligned.

3. Monitor the bellows regularly for indications of use, damage, or leakage.

4. Replace the bellows as required.

Service and Maintenance

To ensure that your metal bellows carry on to work precisely and properly, it is important to perform service that regular upkeep. This includes:

- Regular inspections to check always for signs of wear, damage, or leakage

- Regular cleaning to eliminate any debris or contaminants that may have accumulated

- Lubrication to make sure that the bellows can smoothly go easily and

- Replacement of any used or components that are damaged

Quality of Metal Bellows

Whenever metal that choosing, it really is important to look for high-quality components that are constructed with durable materials and produced to strict quality standards. Some facets that are important consider include:

- Material quality: Look for bellows which can be made from high-quality, corrosion-resistant metals such as for example titanium or steel that stainless.

- Manufacturing quality: Look for bellows which can be manufactured using advanced strategies such as for instance for instance laser-welding or precision machining.

- requirements conformity: Look for bellows that comply with industry criteria such as ASME or ISO.

Applications of Metal Bellows

Metal bellows are used in a range that wide of, including:

- Automotive engines and systems which are exhaust

- Aerospace applications such as for example aircraft machines

- Industrial pipelines and machinery

- Medical devices such as ventilators and oxygen concentrators

- Vacuum systems and pressure chambers

Metal bellows are an innovative and component that versatile have numerous advantages and can be used in a wide range of applications. Whether you're looking for metal ripple pipe a durable and flexible expansion joint for your engine or pipeline, or a high-quality component for your medical device or vacuum system, metal bellows are an choice that exemplary. By using safety that appropriate, doing regular service and upkeep, and choosing high-quality components, you can make sure that your metal bellows carry on to function properly and safely for a long time to come.

Comments

Post a Comment